Tell us about yourselves.

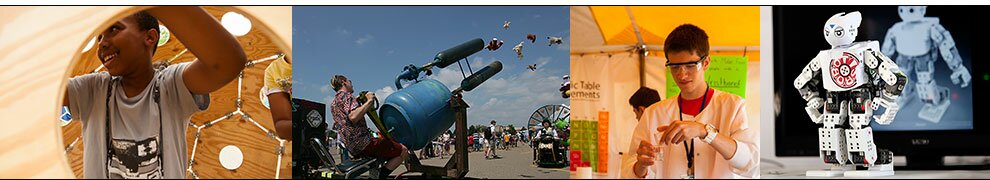

I’m a technician working at Henry Ford. I’m basically a tinkerer, and my son Blade is the kind of kid that is very into electronics- he’s a very modern child. He’s good with tablets and computers, so it’s hard to impress him. He and I are both good at different things- while he’s figuring out how to code Minecraft, I’m busting trying to figure out how to make his Nerf gun shoot through drywall. But we always try to do little projects together, and the team here at work are all tinkerers in their own right too. We’re just typical makers- people who look for problems and find different solutions to try to fix them.

What inspired your project?

Basically, raising kids right now is a tricky challenge because there’s so much to distract them- they’re so wrapped up in technology and literally everything is at their fingertips. So the inspiration was to show kids that just because the instructions say do it this way, it doesn’t mean that you have to go that route, and also that you can take engineering and science and use it to push something beyond its design. To find weakness and trying to either change or modify it to go beyond that. The whole thing started 2013, when I noticed a Hot Wheel kit that my son had gotten for his birthday where you actually put the track on the wall and I started wondering if we could take this past what’s on the box. My son and I started taking the connectors off the wall and taping them in different positions and making it bigger and bigger. Before we knew it we had a 48-inch loop and we were dropping cars from the ceiling. It was basically the height of our playroom. This got me thinking that we could go further- go for a world record if there was one, which there was.

How long did it take to complete?

The original project took about two-month start to finish once we got the team put together. The only thing we didn’t make ourselves was the Hot Wheel track itself, but the superstructure we custom cut and set up. To physically assemble it only took a few hours. It probably took longer to create the design and build the materials than to actually make it.

What was the biggest challenge in making it?

Probably organization was my biggest challenge, that, and finding the right people to work on it. Luckily, I pitched it to the right people and they all jumped on board.

After it was built there were some minor tuning issues, we had to figure out if we could actually get these little cars to go around a twelve foot loop, but it was really just a matter of using the right people, figuring out what abilities they had and what our capabilities were and getting that all to go into the same direction once you have the parts- everyone’s talents just come together.

Do you have plans to build an even larger track?

Yes, if our record gets broken by someone else, then we think we’d be able to successfully reclaim our title. We learned a lot from this attempt and we already have some ideas on how we might make it bigger. There’s have enough ceiling height at our facility, so with a couple of tweaks we think we could possibly make it even larger.

What are you most looking forward to at Maker Faire Detroit this year?

Maker Faire is such a big event that I’m really hoping we’ll be able to show our track to a lot more kids and parents. To really tell them that this is something you can do. Working on a project like this is not so massive, it’s not the space program. It just takes the desire to apply concepts, to do some practical experimentation, and implement it. So I’m really looking forward to being able to share that with more parents and more kids, to really get the ideas going. I want someone in that group to go “I can do that, I can beat it,” and try and beat the record, and then we’ll take it right back.